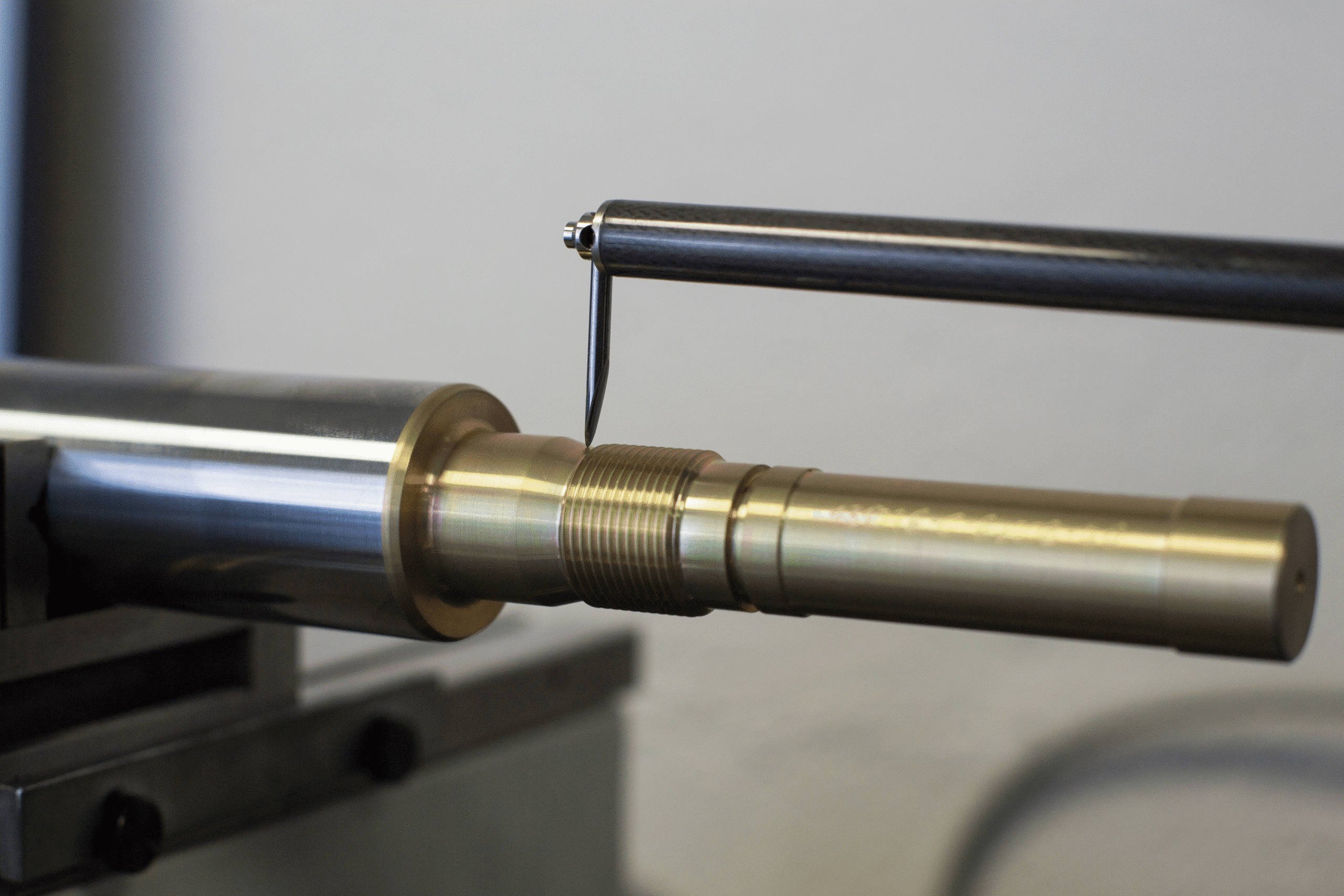

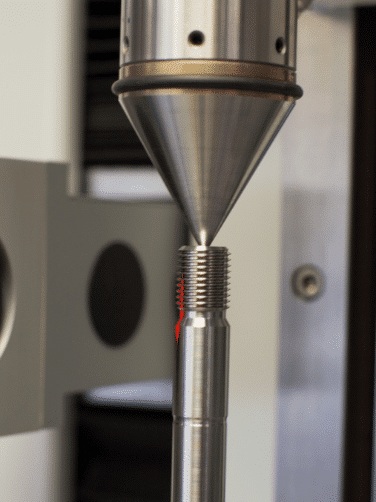

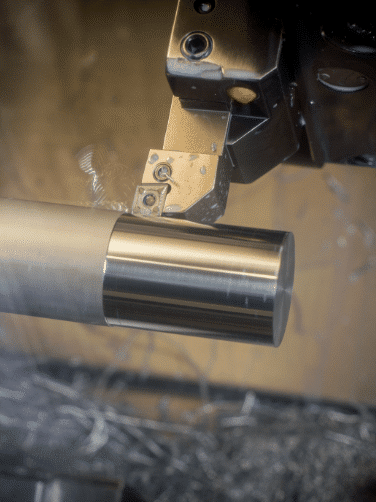

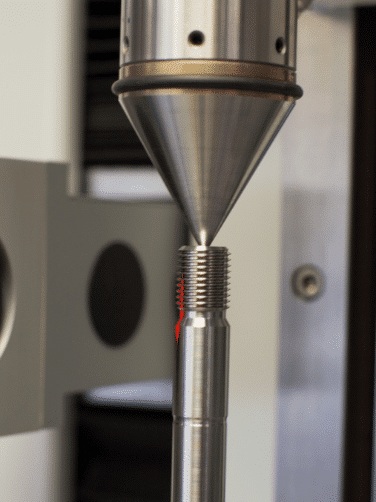

Based in Saumur, between Angers and Tours, and 3 hours from Paris, we specialize in turning, milling, grinding and fitting of technical parts, mainly of small dimensions and manufactured in small or medium series. AAS industries machines all types of materials (steel, stainless steel, aluminum, inconel, titanium, copper, peek or other plastics) from bars, billets, foundries or forged blanks.

Experts in high-precision mechanics

Since 1976

Certix group dolor sit amet, consetetur sadipscing elitr, sed

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum.

Discover the groupAAS industries experts in high-precision mechanics

A fully integrated process from multi-source sourcing to kitting or kanban shipment management

AAS industries manages complex bills of materials and offers a complete service including – in addition to precision mechanics – in-house assembly services, electrical and electronic wiring, and the assembly orintegration of mechanical and electromechanicalsub-assemblies. Thanks to a network of accredited subcontractors, we can manage all types of special processes in a fully integrated way: surface treatment, heat treatment, adhesion…. We provide you with a complete service and deliver a product or sub-assembly ready for assembly.

Our culture and values

AAS Industries is founded on 4 core values:

Putting people first

The company’s greatest asset is the men and women who work for it. Recognized for the technical expertise and professionalism of its teams, AAS industries intends to capitalize on this strength and continue to strengthen its workforce, both qualitatively and quantitatively.

Quality

EN 9100 certified for 15 years, quality and continuous improvement permeate every one of the company’s processes, whether purely internal or involving third parties (customers, suppliers, service providers, etc.).

Listening, commitment and customer service

AAS industries works in close collaboration with its customers, most of whom have placed their trust in us since the very beginning. This proximity is underpinned by the availability of our teams and the flexibility of our organization and production resources.

Training policy

The turning and milling workshop operates in shifts (2 x 8), with the rest of the workshop working normal hours. In the workshop, our journeymen all have extensive experience and solid technical skills. With an average age of 46 and an average length of service of 19 years, AAS industries can count on experienced and loyal employees.

Notre histoire

AAS Industries lorem ipsum dolor set amet

- 1976

- 1986

- 1997

- 2005

- 2018

- 2019

Company founded in Saumur (49) by ABG SEMCA group

(subsidiary of Thomson CSF then Liebherr Aerospace). Its main activity is precision mechanics for the aerospace, defense and medical industries.

Takeover of AAS by German group Fresenius Medical Care.

Strong growth in the medical business, particularly in the assembly of generators for dialysis machines.

Fresenius withdrawal

and refocusing on the aerospace and defense sectors.

First EN 9100 certification

(and ISO 9001)

Takeover of AAS by David LECOMTE and participation in the Industrie du Futur program

Launch of a major transformation plan for the company.

Implementation of the transformation and investment plan

with the arrival of the new Index G220 milling lathe and the deployment of our new ERP SAGE X3 enhanced by 4CAD's aero vertical.

1976

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum.

23

machining journeymen. Turners, millers, grinders, fitters and warehousemen

5

helpers with assembly, wiring and fitting

4

quality and control technicians

8

employees for production management, purchasing, supply chain logistics, sales administration and accounting/finance