High-precision machining

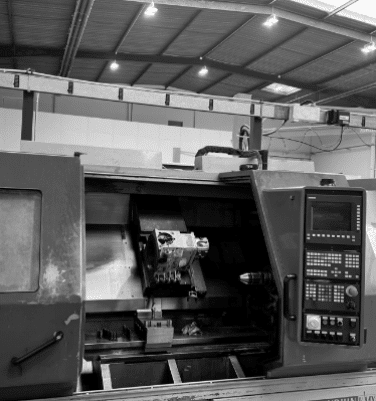

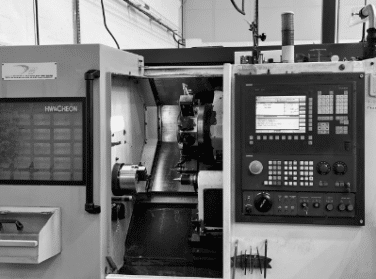

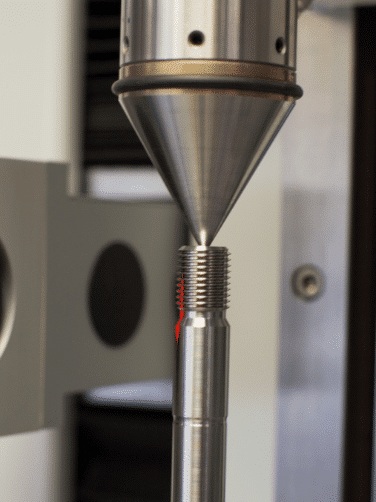

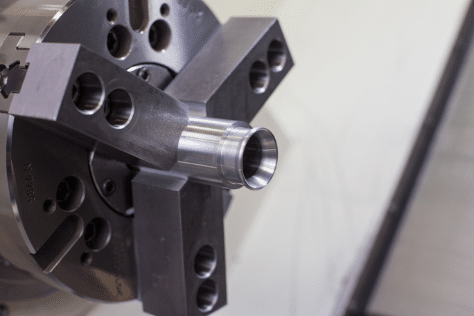

Turning

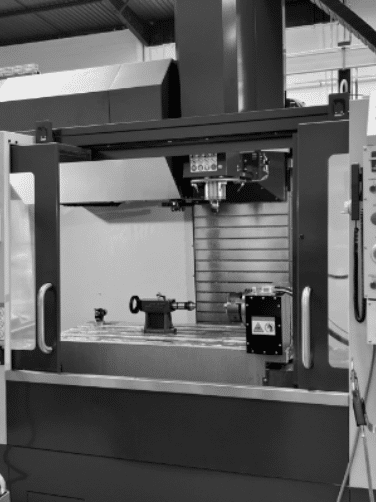

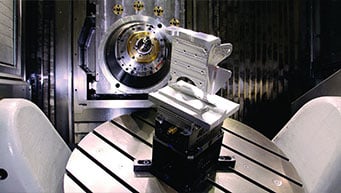

Milling

Grinding

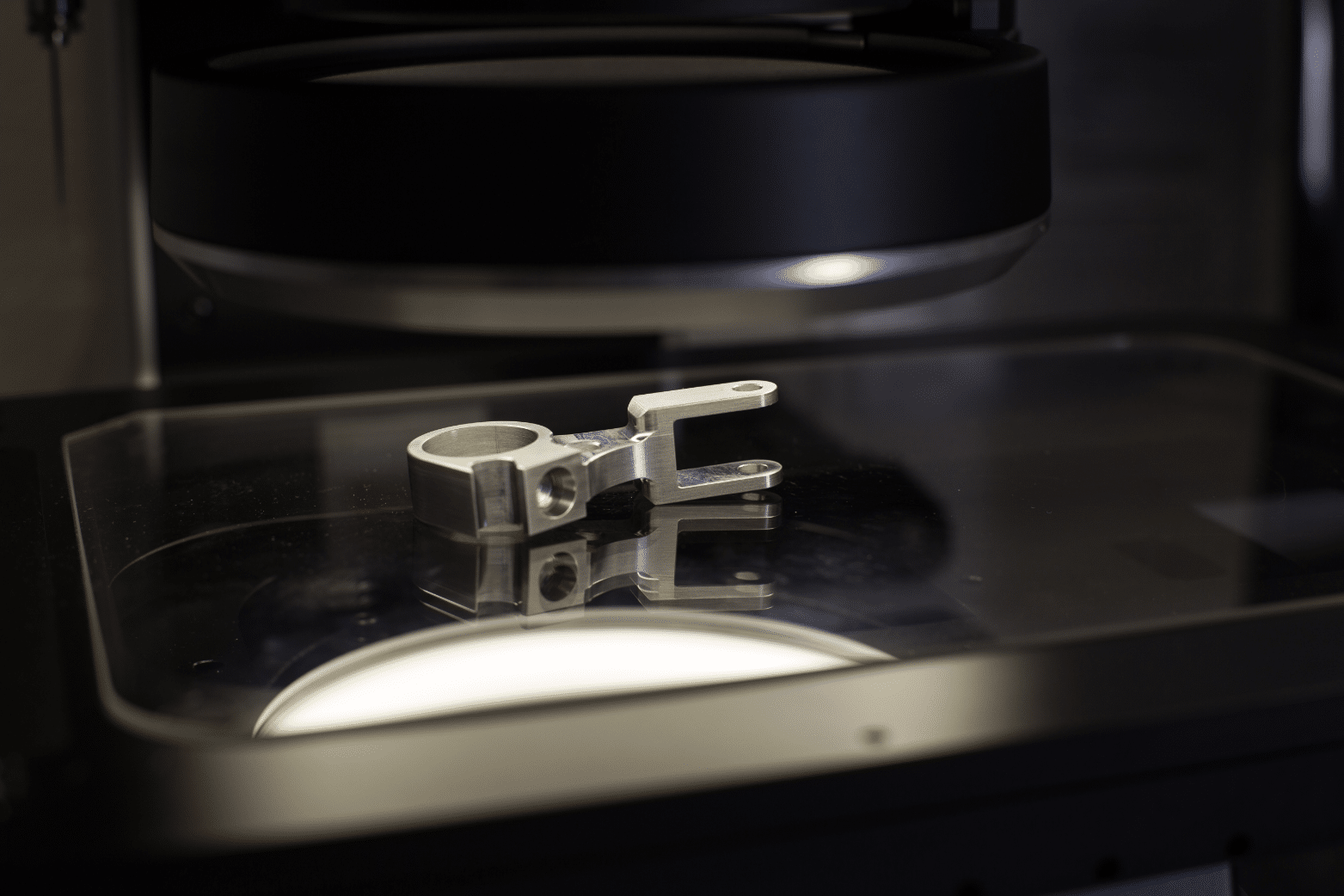

Adjusting, finishing

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed

Based on specifications and 2D or CAD drawings supplied by its customers, AAS Industries carries out high-precision machining of small technical parts, with tolerances ranging from a few hundredths to a few microns. AAS Industries machines all types of materials (steel, stainless steel, aluminum, inconel, titanium, cuprous, peek, etc.) in bar or slug form, from foundries or forging blanks, and is particularly competitive for small (prototype, multi-unit and pre-production) and medium-sized production runs of parts. Most of our production incorporates one or even two surface treatments, and therefore requires rigorous management of production cycles which, in some cases, can exceed 12 or 18 months, including procurement.

Shooting

Lorem ipsum dolor sit amet, consetetur sadipscing elit.

At the heart of AAS industries’ business for over 40 years, with around 70% of the workshop’s capacity, turning operations are carried out by journeymen working in 2 shifts, all experienced and autonomous operators, including for set-up phases, programming and 1st part checks. Operators also make their own tooling and carry out deburring operations at the workstation or on machines when possible.

Index, Nakamura and Mori Seiki CNC lathes are equipped with bar feeders and can handle bars up to 65 mm in diameter or billets up to 250-300 mm in size. Most lathes are twin-spindle, twin-turret with milling unit, and carry magazines for up to 140 tools. The Index G220 and the DMG MORI NTX1000 also offer 5-axis continuous turning capability.

AAS Industries has also preserved its resources and means for machining on traditional lathes, for example for crimping and loosening operations.

Milling

Lorem ipsum dolor sit amet, consetetur sadipscing elit.

AAS boasts extensive milling capabilities, with 5 3-axis and 4-axis machining centers from Mori Seiki and Mazak, including 3 vertical and 2 horizontal. The latter two can accommodate tool magazines of up to 120 tools, are palletized (400 x 400 mm tables) and are equipped with workpiece and tool probes for greater machine capability.

Rectification

Lorem ipsum dolor sit amet, consetetur sadipscing elit.

AAS Industries is able to complement turning/milling operations with finishing operations carried out by a team of highly qualified professionals operating a fleet of 8 conventional and digital (Studer CNC) grinding machines.

Whether surface grinding or internal and external cylindrical grinding, AAS is able to meet the most demanding surface finishes, as well as the tightest dimensional and geometric tolerances, even on very hard materials (by nature or after heat treatment).

Fitting and finishing

Lorem ipsum dolor sit amet, consetetur sadipscing elit.

Whether for a finishing operation designed to achieve a very high level of aesthetic finish on parts, or for corrective trimming/deburring, AAS has the capabilities needed to deliver parts with impeccable dimensions and appearance: deburring under binocular or video endoscope, polishing, lapping, tribofinishing room.

Our machinery

AAS Industries lorem ipsum dolor set amet

6

Drills of different capacities

8

Rodeuses

1

Dual-spindle multifunction lathe

20

CNC lathes, including 2 3-axis and 4 2-axis lathes

11

3-, 4- and 5-axis machining centers

Photo gallery of machines and achievements

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor

Drag the cursor.

Our modern machinery, equipped with robots and bar feeders, enables us to react quickly to customer requests.

Our strengths

Our certifications and labels

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam.